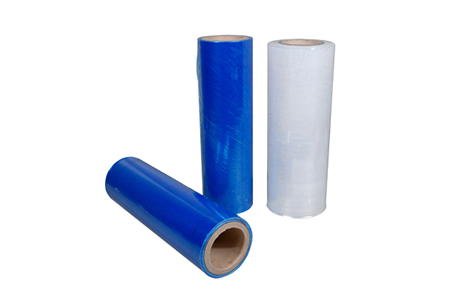

Uses colors are:

Transparent PE protective film, PE blue protective film, black and white film surface viscosity PE protective film protective film without leaving adhesive residue

PE protective film performance indicators:

Press tack main points are: ultra-low viscosity protective film, low viscosity protective film, low viscosity protective film, the sticky protective film, protective film viscosity, high viscosity protective fil

1. Ultra-low viscosity protective film (ie micro-bottom stick): Thickness: 3c to 10c

Features: Thick (≥0.03m ± 0.003), width (≤1.3), high (100-1500), the substrate (PE), peel strength (≤5g / cm), temperature (60), an elongation (> 400)

Purpose: Easy to use and easy to paste easy to tear, no residue of glue applied to the organic sheet, instrumentation, display, glass lenses, plastic lenses and other.

2. Low viscosity protective film

Features: Thick (≥0.03m ± 0.003), width (≤1.3), high (100-1000), the substrate (PE),

The peel strength (10-20g / cm), temperature (60), an elongation (> 400)

Purpose: tack stability, attached is good, good performance and then peeling off, no residue phenomenon, for steel mirror panels, titanium, smooth plastic plate, screen printing, and other prestigious Ming.

3. Low viscosity protective film

Features: Thick (≥0.03m ± 0.003), width (≤1.3), high (100-1000), the substrate (PE),

The peel strength (30-50g / cm), temperature (60), an elongation (> 400)

Purpose: tack stability, attached is good, good performance and then peeling off, no residue phenomenon, applied to furniture Polaroid board, stainless steel, ceramic tile, marble, artificial stone and so on.

4. The sticky protective film

Features: Thick (≥0.05 ± 0.003), width (≤1.3), high (100-1000), the substrate (PE),

The peel strength (60-80g / cm), temperature (60), an elongation (> 400)

Purpose: tack stability, attached is good, good performance and then peeling off, no residue of glue applied to fine lines matte board and general difficult to stick material surface protection.

5. Viscosity protective film

Features: Thick (≥0.05 ± 0.003), width (≤1.3), high (100-800), the substrate (PE),

The peel strength (80-100g / cm), temperature (60), an elongation (> 400)

Purpose: tack stability, attached is good, good performance and then peeling off, no residue of glue applied to fine lines matte board, aluminum panels, difficult to stick plastic sheet metal.

6. Ultra-high viscosity protective film

Features: Thick (≥0.04 ± 0.003), width (≤1.3), high (100-800), the substrate (PE),

The peel strength (40-60g / cm), temperature (60), an elongation (> 400)

Special high viscosity, use water-based acrylic pressure-sensitive adhesive for easy to use, easy to paste easy to tear, no residue of glue is suitable for coarse grain aluminum and other materials difficult to stick.

Related tags:PE protective film